Innovations in Oil & Gas Component Manufacturing

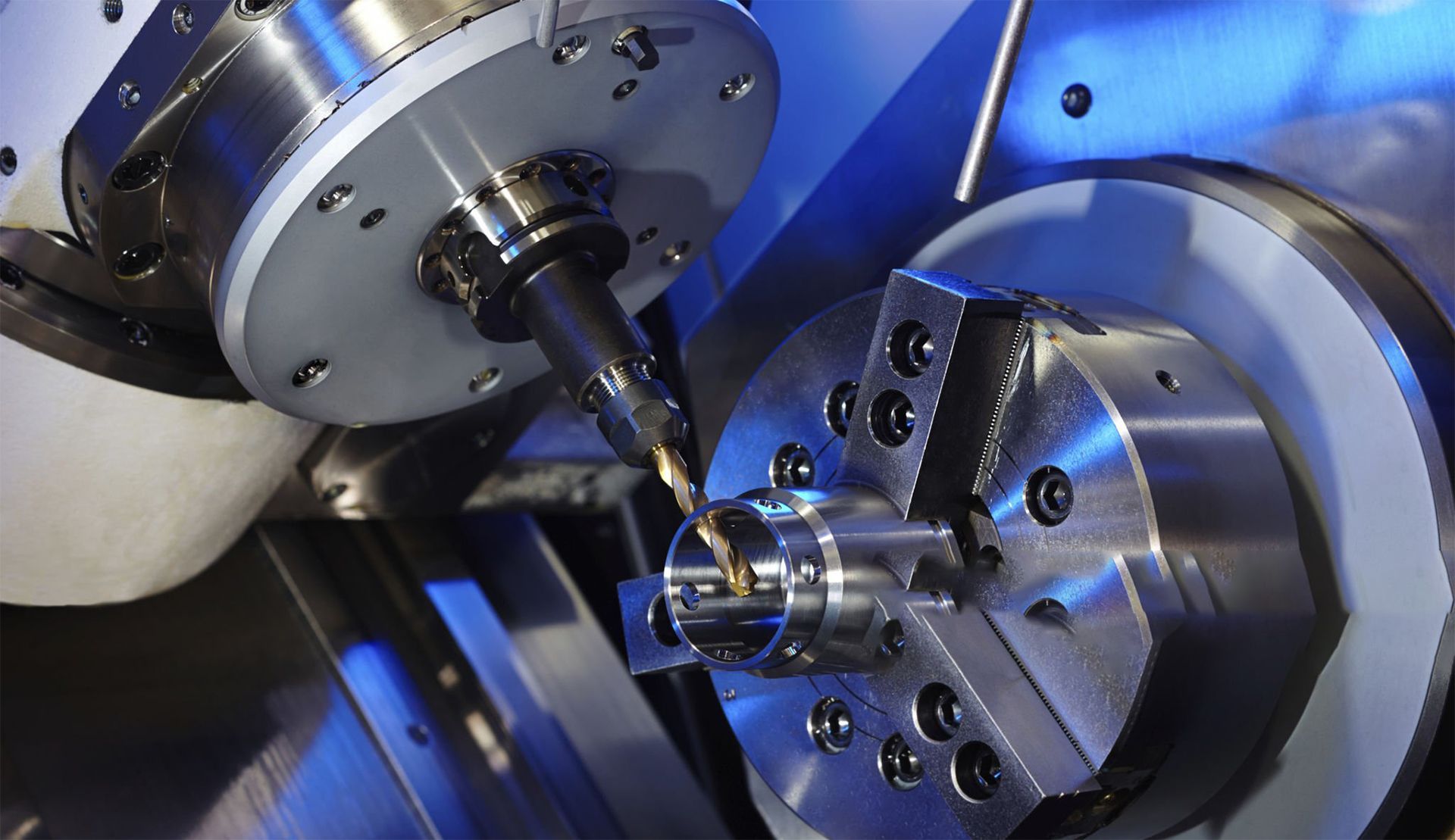

Advanced CNC Machining for Enhanced Precision

The oil and gas industry demands components that can withstand extreme conditions, from high pressures and temperatures to corrosive environments. Precision engineering plays a critical role in ensuring the durability and reliability of these components, and recent innovations in manufacturing are pushing performance standards even further.

CNC machining has transformed oil and gas component production by enabling ultra-precise manufacturing with tight tolerances. Multi-axis machining allows for complex geometries in critical parts such as valves, drill heads, and pipeline connectors, ensuring optimal performance and longevity in the field.

Material Advancements for Durability

Innovations in material science, including high-performance alloys and coatings, have significantly improved resistance to wear, corrosion, and extreme temperatures. CNC machining techniques can now accommodate these advanced materials, extending the lifespan of vital components and reducing maintenance costs.

Automation & Digital Manufacturing

The integration of automation and digital manufacturing technologies, such as AI-driven quality control and predictive maintenance, has improved production efficiency. Real-time data monitoring ensures consistent quality and reduces downtime, allowing for faster turnaround times without compromising precision.

The Future of Oil & Gas Component Manufacturing

As the industry evolves, advancements in additive manufacturing (3D printing) and hybrid machining are opening new possibilities for customised, high-strength components. These innovations are driving greater efficiency, sustainability, and performance in oil and gas operations.

At B&R Precision Engineering, we specialise in producing high-quality, precision-engineered components for the oil and gas sector. Contact us to learn how our expertise and cutting-edge technology can support your next project.