Enhancing Efficiency in Automotive Manufacturing with CNC Machining

Precision and Consistency in Automotive Manufacturing

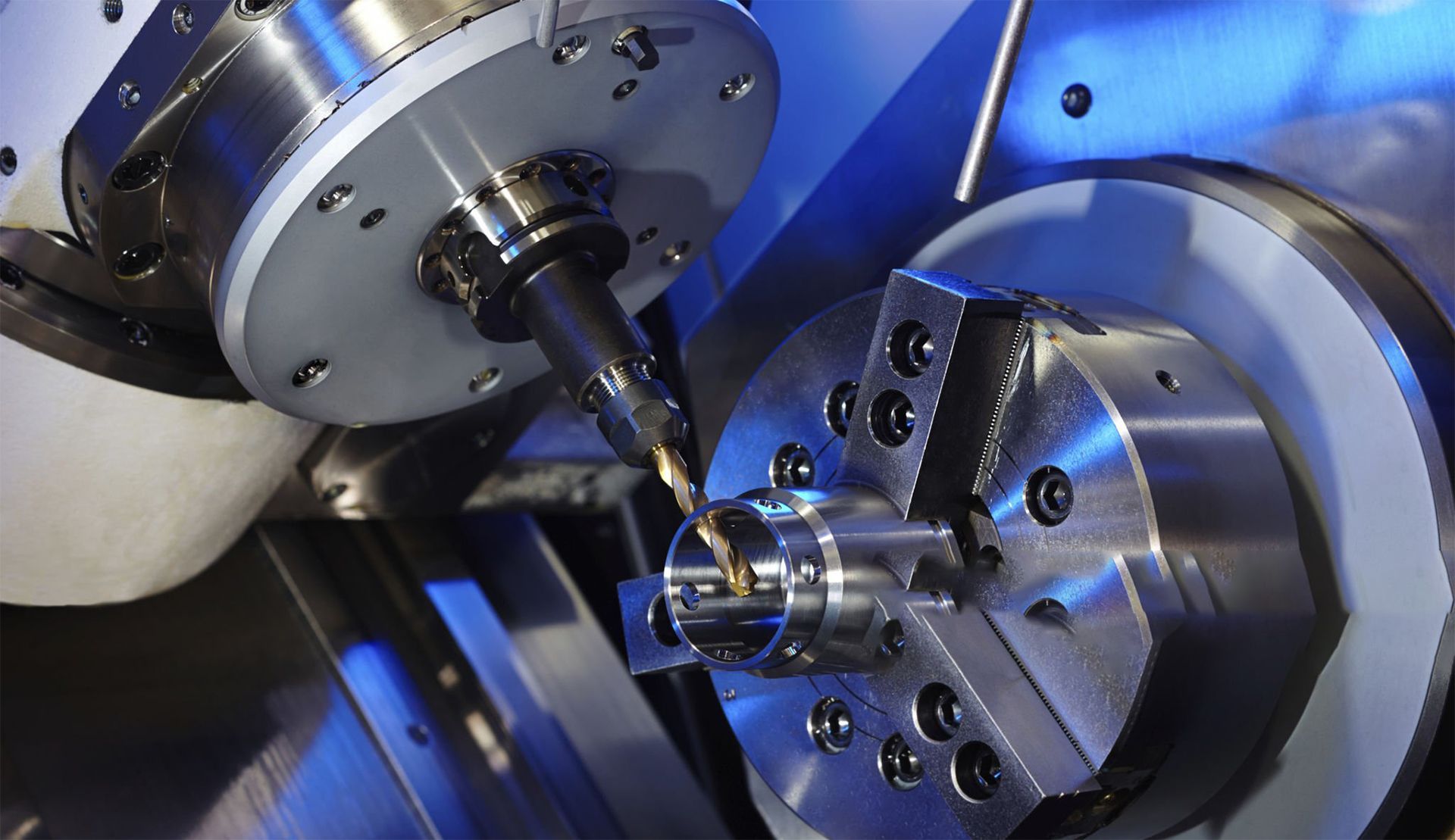

The automotive industry is built on precision, efficiency, and innovation, with manufacturers constantly seeking ways to improve performance, reduce production times, and maintain the highest quality standards. CNC (Computer Numerical Control) machining has become a cornerstone of modern automotive manufacturing, ensuring components are produced with extreme accuracy and consistency. From engine parts and suspension systems to custom brackets and gear components, CNC machining delivers high-tolerance, repeatable results that are essential for both high-performance and mass-production vehicles.

CNC machining eliminates human error by automating the cutting, milling, and shaping of materials with micron-level precision. This ensures that every component fits perfectly within an assembly, reducing wear and tear and enhancing overall vehicle performance. High-speed machining capabilities also allow for faster production times while maintaining superior quality, making CNC technology indispensable for automotive manufacturers.

CNC Machining’s Impact on Future Automotive Innovations

As the industry shifts towards electric vehicles (EVs), hybrid systems, and lightweight materials, CNC machining plays a crucial role in advancing automotive technology. The precision required for battery housings, electric motor components, and aerodynamic enhancements demands cutting-edge machining techniques. Additionally, the growing focus on sustainability means manufacturers must optimise material usage and minimise waste—something that CNC machining achieves through efficient, automated production processes.

By integrating high-precision CNC machining into automotive manufacturing, companies can enhance vehicle performance, reduce production costs, and drive the future of mobility.