The Role of CNC Machining in High Performance Automotive Engineering

Why CNC Machining is Essential in Automotive Engineering

n the world of high-performance automotive engineering, precision, reliability, and innovation are key. Whether it’s for motorsport, supercars, or advanced vehicle manufacturing, every component must be engineered to exact specifications to ensure maximum efficiency and durability. This is where CNC (Computer Numerical Control) machining plays a vital role.

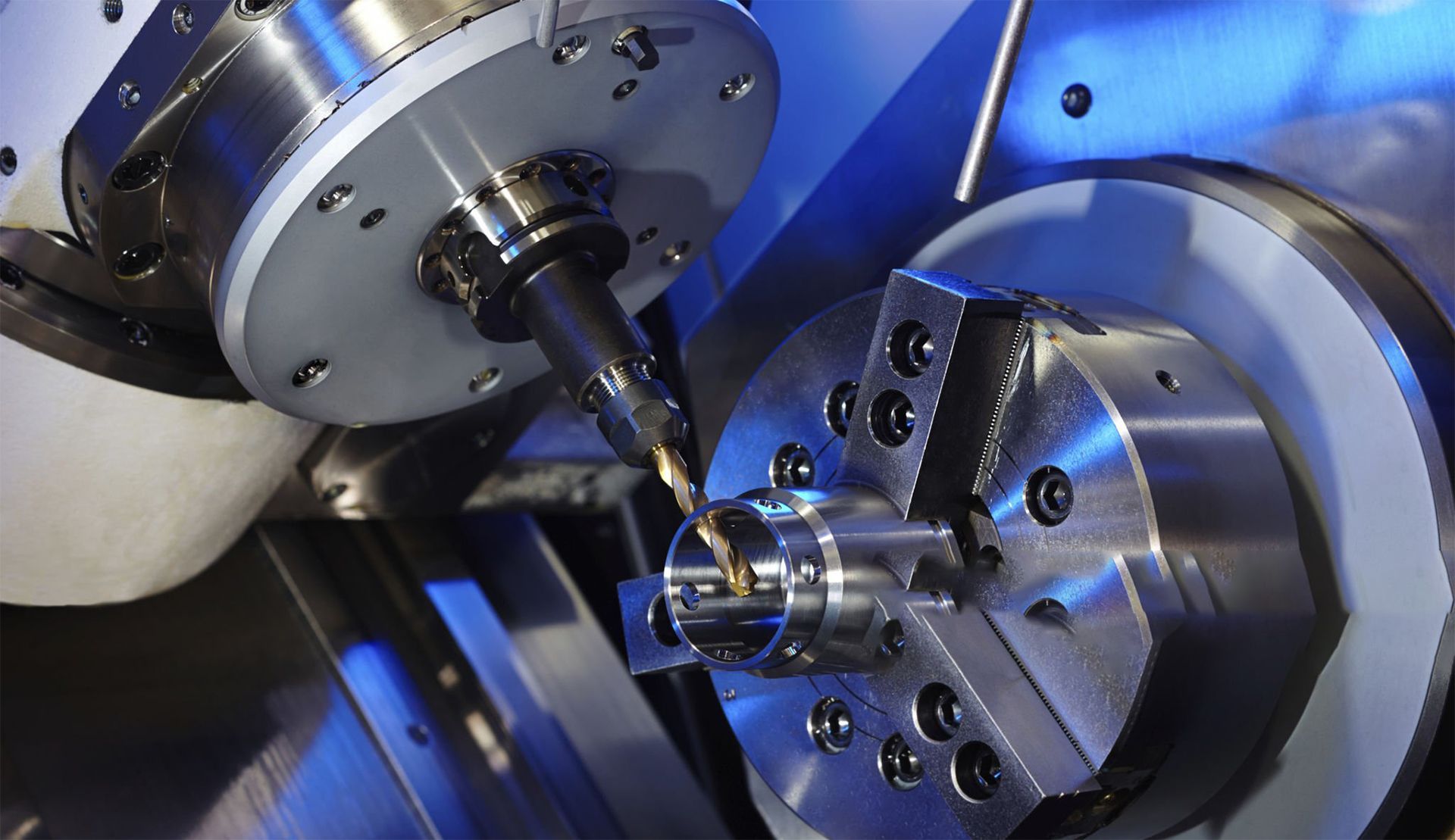

CNC machining has revolutionised the automotive industry by providing an unparalleled level of precision and consistency in manufacturing complex components. Unlike traditional machining methods, CNC technology automates the cutting, milling, and shaping of materials with extreme accuracy, reducing errors and enhancing production efficiency.

Key Benefits of CNC Machining in High-Performance Vehicles

Unmatched Precision

CNC machining ensures tight tolerances, often within microns, which is crucial for high-performance automotive parts like engine components, suspension systems, and transmission housings.

Material Versatility

High-performance vehicles require lightweight yet durable materials such as aluminum, titanium, and carbon composites. CNC machining handles a wide range of materials with ease, ensuring strength without unnecessary weight.

Rapid Prototyping & Customisation

Automotive innovation requires rapid iteration and testing. CNC machining enables quick prototyping of new designs, allowing engineers to refine performance components before full-scale production.

Durability & Performance Enhancement

Parts produced through CNC machining are more durable and resistant to extreme conditions, ensuring longevity in high-stress environments like racing or performance driving.

Common CNC-Machined Components in High-Performance Vehicles

Engine Components

Cylinder heads, pistons, and intake manifolds require high precision to optimise combustion and efficiency.

Suspension & Chassis Parts

CNC machining creates lightweight, high-strength suspension arms, brackets, and mounts for superior handling.

Brake System Components

Performance brake callipers and discs must be machined with exact precision to withstand high temperatures and pressures.

Transmission & Drivetrain Parts

CNC machining ensures smooth, reliable performance in gearboxes, differentials, and drive shafts.

The Future of CNC Machining in Automotive Engineering

As automotive technology advances, CNC machining continues to evolve with new innovations such as 5-axis machining, automation, and AI-driven manufacturing. These advancements allow even more complex geometries, improved efficiency, and reduced production times, shaping the future of high-performance vehicle engineering.

At B&R Precision Engineering, we specialize in delivering high-quality CNC-machined components for the automotive industry. With cutting-edge technology and expert craftsmanship, we ensure every part meets the highest standards of precision and performance.